1. What Is an NC Lathe and Its Purpose?

An NC lathe, commonly referred to as a CNC lathe (ЧПУ токарный станок)or CNC lathe machine (CNC-Drehmaschine), is specifically designed for machining non-ferrous metals, including iron, aluminum, copper, stainless steel, and various plastics. The versatility of the CNC lathe allows it to produce high-precision components efficiently. With different configurations and functionalities available, selecting the right automatic lathe can often be a daunting task for many customers. In this article, we will introduce Tai’an Haishu CNC lathes to help you understand what type of automatic lathe you should consider purchasing and provide insights into the pricing of CNC lathes (máy tiện CNC).

1.1 Key Features of NC Lathes

- Precision Machining: NC lathes are designed to achieve high levels of accuracy and repeatability, making them ideal for producing complex geometries.

- Versatility: CNC lathes (مخرطة CNC) can machine a variety of materials and handle different operations such as turning, milling, and drilling.

- Automation: Modern NC lathes often have automated features that enhance productivity and reduce manual labor requirements.

2. How to Choose the Right NC Lathe?

2.1 Important Configurations to Consider

When selecting a CNC lathe, several critical configurations must be taken into account:

- CNC System: The backbone of any CNC lathe, the system determines how the machine is programmed and operated.

- CNC Tool Turret: This component holds the cutting tools and is essential for efficient machining.

- Chuck Type: The chuck secures the workpiece during machining and can vary significantly in functionality.

- Tailstock: Important for supporting longer workpieces, the tailstock can impact the machine’s overall capabilities.

- Feeder Options: These can improve automation and efficiency in production.

2.2 Recommended CNC Systems

When it comes to CNC systems, well-known brands like Germany’s Siemens, Japan’s Fanuc and Mitsubishi, and Taiwan’s New Generation are highly regarded for their reliability and performance. However, these systems often come with higher costs and complex service requirements.

We recommend considering GSK and KND systems, which are domestic options that support all G-codes and M-codes, as well as various composite cycle programs and macro programs. They are compatible with mainstream CNC lathe programming software and can accommodate custom functionalities based on customer needs. Most importantly, these systems are cost-effective, offering prompt post-sales service and debugging.

3. What Are the Chuck Options for an NC Lathe?

3.1 Choosing the Right Chuck Type

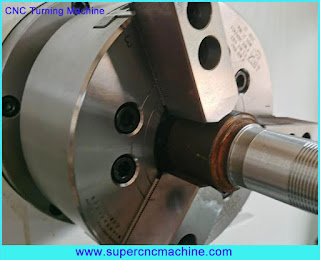

When you purchase a CNC lathe machine, chuck selection is crucial for achieving optimal performance.

- Three-Jaw Manual Chuck: Commonly used on flat bed CNC lathes, this manual chuck provides strong universality but works slowly due to its manual operation.

- Three-Jaw Hydraulic Chuck: Often preferred for inclined bed CNC lathes, this chuck allows for automatic clamping of workpieces. Although it requires longer setup times and adjustments, it is favored for automated processing due to its hydraulic power output, which offers a higher compression ratio than pneumatic options.

3.2 Tai’an Haishu Chuck Options

Tai’an Haishu allows customers to choose between three-jaw and four-jaw chucks based on their machining needs. When ordering your CNC lathe, it’s essential to specify your preference to ensure optimal performance.

4. What Is the Role of the CNC Tool Turret in an NC Lathe?

4.1 Importance of the Tool Turret

The CNC tool turret is a vital component of any automatic lathe, as it holds the cutting tools and facilitates quick tool changes.

- Electric Tool Holders: Typically available in 4, 6, or 8 station configurations, electric tool holders are popular due to their affordability and ease of replacement. However, they may cause vibrations during heavy machining due to their thinner body.

- Hydraulic Servo Tool Turrets: For higher machining demands, hydraulic servo tool turrets are preferred. These turrets provide quick tool changes while maintaining strong rigidity, making them suitable for heavy machining applications. They also allow for the installation of powered tools such as drills and milling cutters, enabling a combination of operations like turning and milling.

5. How Does the Tailstock Function in an NC Lathe?

5.1 Understanding Tailstock Functions

The tailstock is another important feature of CNC lathes (CNC torna tezgahı), especially for processing long shaft workpieces. Shorter bed CNC lathes (torno CNC) typically lack a tailstock unless it is necessary to support longer workpieces against vibration.

5.2 Tailstock Power Options

- Manual Tailstocks: Require human effort to operate and can be prone to slipping.

- Pneumatic Tailstocks: Use air for driving and are suitable for lighter machining loads.

- Hydraulic Tailstocks: Ideal for heavy or long workpieces, providing a firm grip and stability.

Choosing the right tailstock option based on your specific needs is crucial for effective machining.

6. How Does Tai’an Haishu Support Your NC Lathe Needs?

6.1 Commitment to Quality and Customization

Tai’an Haishu is a leading manufacturer specializing in CNC lathes, focusing on design, manufacturing, sales, and service. Our CNC machine tools are recognized for their high cost-performance ratio and robust customization capabilities.

6.2 Invitation to Visit

We invite customers interested in CNC lathe machines to visit our factory, where we can showcase the advanced technology and capabilities of our CNC lathes. This visit will provide insights into how our products can meet your specific machining needs.

7. Conclusion

In conclusion, understanding the components and functionalities of an NC lathe is essential for making informed purchasing decisions. With various configurations available, including CNC systems, chucks, tool turrets, and tailstocks, the right setup can greatly enhance your machining capabilities. Tai’an Haishu offers a wide range of CNC lathes designed to meet diverse industrial requirements. For more information or inquiries, please contact us or arrange a visit to our facility.