Mr. Saeed is from IRAN, he is a reseller, he bought our CNC lathes before, He trusts us very much and we have established a good partnership. This time his customer needed the CNC machine center with four axes and ATC 20 tools. I sent to him the XH7125 and VMC850 specifications, his customer checked them and thought that the model VMC850 was the best for his requirements. So he ordered 2 sets of CNC machine center VMC850 this time

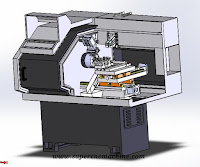

CNC Machine Center VMC850 Specifications

| Item | Detail | Unit | Specification |

|---|---|---|---|

| Stroke | Moving range X、Y、Z | mm | 850×450×500 |

| Nose to a rotary table (horizontal) distance | mm | 150-650 | |

| Spindle center to column guideway surface distance | mm | 560 | |

| Feed | Fast moving speed X、Y、Z | m/min | 30/30/24/min |

| Cutting feed rate X、Y、Z | mm/min | 10~15000mm/min | |

| Spindle | Spindle taper | BT40 | |

| Spindle speed | r/min | 40~6000rpm | |

| Main motor power | kw | AC servo 7.5 | |

| Maximum torque | nm | 70 | |

| Machine Size | L×W×H | mm | 2500×2300×2300 |

| Net weight | kg | 4800 | |

| Gross weight | kg | 4900 |

4 Axis CNC Machining Center VMC850 Features

1.Robust box-way castings

2.High speed, low noise ball screw and wide linear guideways on three axis

3.High rigid machine frame to fit high accelerations

4.Famous brand tool magazine

5.High volume, high-pressure spindle coolant

6.Direct drive spindle with standard speed 8000rpm

7.Rapid feed to reduce Non-machining time

8.High speed for mass production

2.High speed, low noise ball screw and wide linear guideways on three axis

3.High rigid machine frame to fit high accelerations

4.Famous brand tool magazine

5.High volume, high-pressure spindle coolant

6.Direct drive spindle with standard speed 8000rpm

7.Rapid feed to reduce Non-machining time

8.High speed for mass production

About HAISHU Machinery

As the professional CNC machine designer and manufacturer, Taian Haishu Machinery Co., Ltd (Haishu Machinery) is the high-tech enterprise specialized in CNC machinedevelopment, production, sales and service since 2001. We have more than 30 professional talented CNC experts and more than 12,000 square meters manufacturing factory. More than 16 series 80 kinds of CNC machines and related parts had been manufactured to satisfy your pumping requirements. Our high quality and innovative products include CNC lathes, CNC milling machine, CNC machining center, CNC turn-mill machine, CNC tool grinding machine, CNC pipe threading lathe, CNC wood lathe, stone CNC machine, CNC root canal file grinder and custom CNC equipment for special requirements.