CNC turning centers are the mainstream modern CNC lathes. This kind of CNC lathe machine is equipped with a power head for complex metal machining.

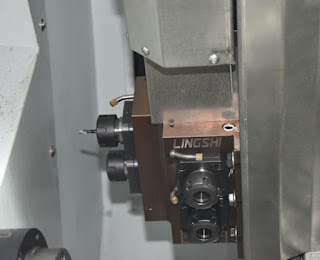

The CNC turning process involves material being secured to a spindle within a CNC machine, and a cutting tool moving in a linear fashion acts upon the material and removes undesired material until the finished component that is left. CNC turning centers with live tools and lathes may seem identical, but they generally refer to slightly different machines. Lathes generally only turn while turning centers can be more advanced. These CNC lathe machines can be capable of facing, threading, knurling, drilling, boring, reaming, and taper turning. CNC turning center is suitable for medium and small batch machining of sophisticated and complex rotary parts. The CNC machine is equipped with power tools. In addition to the turning function, the CNC lathe machine has axial, radial drilling, tapping, and milling functions. This CNC Turning Milling Drilling Machine CK50 features high efficiency, high accuracy, and high performance.

The American customer sent us their workpiece directly and wanted to choose a suitable CNC lathe. After engineers checked, they needed not only a turning process but also tapping and milling. According to the size of the parts, we chose the CNC Turning Centers with Live Tool CK50 for them. At the same time, we sent them the operation videos and parameters. Also we asked for their configuration request. The customer saw the CNC machines and thought this is just suitable for them, so they did not have more requests.

After they determined that they met the requirements, we provided a complete quotation. The customer is very satisfied and recommends immediate execution of the contract to arrange the production.

When the CNC Turning Centers With Live Tool CK50 for them completed, the customer conducted an online inspection. We also sent him the Slant Bed CNC Lathe Machine testing video and Customers are very satisfied with our cooperation again.

CNC Turning Centers With Live Tool CK50 Specifications

| Maximum turning diameter of bed | φ/mm | 510 |

| Maximum turning diameter over Carriage | φ/mm | 180 |

| Maximum processing disk diameter | φ/mm | 400 |

| Maximum radial milling length | mm | 300 |

| Maximum turning length | mm | Row tool 450 Turret 350 |

| X axis (diameter stroke) | mm | 1100 |

| Z axis | mm | 550 |

| X-direction ball screw | 3210-C3 | |

| Recommended X-axis motor torque | N. m | ≥10 |

| Z-direction ball screw | 3210-C3 | |

| Recommended Z-axis motor torque | N. m | ≥10 |

| Bed and horizontal inclination | 30 ° overall casting bed | |

| Rail width | mm | 450 |

| Maximum speed | rpm | 4500 |

| Through hole diameter | mm | 62 |

| Spindle end type | A2-6 | |

| Inner hole taper | MT6 | |

| Recommended spindle motor power | kW | 7.5 |

| Optional hydraulic chuck or collet | 8-inch or 52 collet |

CNC Turning Centers With Live Tool CK50 Configuration

- CK50 system:K1000TF1i,

- 3 PHASE 380v voltage,

- Y axis,

- 2+2 Powerhead,

- 8” hydraulic chuck,

- 8-station hydraulic turret,

- oil brake,

- Magnetic ring encoder,

- Two-axis linear rail,

- 7.5kw servo main motor

About HAISHU Machinery

Our company Taian Haishu Machinery Co., Ltd provides high-precision, high-speed, and high-rigidity CNC machines and related parts. In the face of rapidly changing technologies, we recognize that we need to improve overall performance even further. That is why we are focusing most of our efforts on research and development. Now we have our system, our software, our brand, and our patent. Looking ahead, we still take on board direct feedback from customers and anticipate their needs, so that we can maintain our focus on product development, with an emphasis on CNC lathes, CNC milling machines, CNC machining centers, Slant Bed CNC Turning centers, CNC tool grinding machine, CNC pipe threading lathe, wheel CNC lathe, stone CNC machine, CNC Turning Centers With Live Tool and other high-precision processing machinery, and continue providing products that guarantee customer satisfaction. We hope we can continue to rely on your support in the future.