CNC turret machine tool refers to a turret machine tool equipped with electric or hydraulic or servo motors. A CNC lathe with these turrets can be fitted with a wide variety of tools such as cutting tools, drilling tools, milling tools, and so on.

The CNC turret machine tool is only installed with a manually rotated turret at first, which is inefficient and has poor positioning accuracy. The birth of the CNC turret has solved many drawbacks and improved the processing efficiency of CNC machine tools, which is innovative and creative.

CNC lathes are equipped with different turrets to achieve different functions, and there are various styles for different CNC machine tools. Therefore, when choosing a CNC lathe or a CNC turning-milling compound machine tool, what kind of turret is equipped is particularly important.

The CNC turrets in the CNC turret machine tool have many features, I will introduce them to you.

- Highly flexible

Machining parts on CNC machine tools mainly depends on the processing program. It is different from ordinary machine tools. It does not need to be manufactured, replace many molds and fixtures, and does not need to readjust the machine tool frequently. Therefore, CNC machine tools are suitable for occasions where the processed parts are frequently replaced, that is, suitable for the production of single-piece, small-batch products and the development of new products, thereby shortening the production preparation cycle and saving a lot of process equipment costs.

- High machining accuracy

The machining accuracy of CNC machine tools can generally reach 0.05-0.1MM. The CNC machine tools are controlled in the form of digital signals. Each time the CNC device outputs a pulse signal, the moving parts of the machine tool move by a pulse equivalent (usually 0.001MM), and the machine tool advances. The backlash of the transmission chain and the average error of the screw pitch can be compensated by the numerical control device, so the positioning accuracy of the numerical control machine tool is relatively high. Machining the same batch of parts, on the same machine tool, under the same processing conditions, using the same tool and processing program, the tool travel path is exactly the same, the consistency of the parts is good, and the quality is stable.

- High productivity

The CNC machine tool can effectively reduce the processing time and auxiliary time of the parts. The CNC machine tool has a large range of spindle sound speed and feed rate, allowing the machine tool to perform powerful cutting with a large amount of cutting. CNC machine tools are entering the era of high-speed machining. The rapid movement and positioning of moving parts of CNC machine tools and high-speed cutting have greatly improved productivity. In addition, when used in conjunction with the tool magazine of the machining center, it can realize continuous processing of multiple processes on one machine tool, reduce the turnaround time between processes of semi-finished products, and improve productivity.

- Improve working conditions

Before the CNC machine tool is adjusted, the program is input and started, and the machine tool can automatically and continuously process until the end of the process. What the operator has to do is only program input, editing, parts loading, and unloading, tool preparation, processing state observation, parts inspection, etc. The labor intensity is greatly reduced, and the labor of machine tool operators tends to be intellectual work. In addition, machine tools are generally combined, which is both clean and safe.

CNC turret machine tool can be understood as a CNC lathe that can achieve high precision and high efficiency in modern society. Since it rarely appears in daily life, most small partners should be relatively unfamiliar with it. CNC turret machine tools are generally Divided into in-line and VDI:

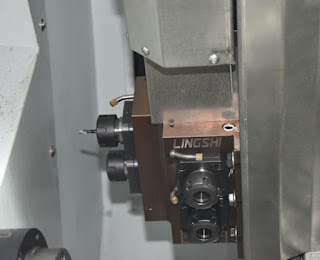

- In-line turret

The in-line turret is to install the CNC turret machine tool directly on the tool holder. Since the in-line turret has few intermediate adapters, the tool has good rigidity after clamping, but it takes time to change the tool. When selecting a tool, the form and size of the tool should be determined according to the width of the turret slot. When installing boring and drilling tools, adapters are required. The tool holder is made of self-boring holes and is not interchangeable. When installing, it should be noted that the machine tool and tool number must be matched. The size of the boring tool and drill bit should refer to the form and size of the adapter holder, and a transition sleeve can be added if necessary.

- VDI turret

VDI-type turrets cannot be installed directly, and various forms of VDI adapters are required. Since these tool holders are mounted on the turret surface, the cantilever is longer and not as rigid as the in-line type. The interface between the VDI turret and the tool holder is mainly determined by the hole diameter of the tool on the end face of the turret. If the hole diameter of the tool is 40mm, the VDI tool holder should choose the VDI40 interface.

In addition, when choosing a tool holder, it should be noted that the VDI tool holder is divided into left and right tool holders, positive and negative tool holders, etc. This should be determined according to the orientation of the machine tool turret and the processing technology.

The right tool holder is used for the turret rear-mounted machine tool; otherwise, the left tool holder is used. Positive and negative tool holders, etc… This is determined according to the orientation of the machine tool turret and the processing technology.

The turret rear-mounted machine tool uses the right tool holder; otherwise, it is the left tool holder.

The selection of positive and negative tool holders must consider two factors at the same time, namely the front and rear of the machine tool turret and the positive and negative rotation of the spindle, which must be correctly selected for normal use.

If you want to know more details about CNC lathe accessories, you can contact me by email, or add my social account.

About HAIAHU

Tai’an HAIAHU is a professional CNC lathe or CNC machine tool manufacturer, we provide customized machine tool services for customers. Including automatic feeding device CNC lathes, and truss feeding CNC machine tools. CNC machining center, and we also develop wheel repair lathes, wheel repair machines, and equipment. Welcome to consult and browse our website.