dvantages Of CNC Lathes

Programmable logic controller (Programmable Logical Controller, PLC for short) is the important part of CNC lathes, it is also a general-purpose automatic control device based on the processor, which is used to complete various logic operations and sequence control of CNC machine tools, such as machine tool start and stop, workpiece Auxiliary actions such as clamping, tool change, coolant switch, etc. PLC also accepts the instructions of the machine tool operation panel. On the one hand, it directly controls the action of the machine tool; The PLC in the CNC lathe machine has a built-in type and independent type.

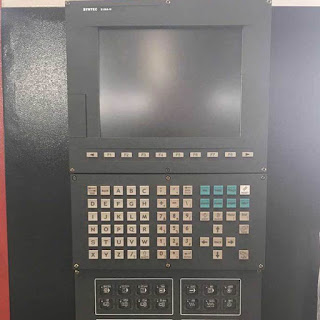

The operation of the numerical control machine tool is realized through the man-machine operation panel, which is composed of the numerical control panel and the machine tool panel.

The CNC panel is the operation panel of the CNC system, which consists of a display and a manual data input (Manual Data Input, MDI) keyboard, also known as the MD panel. The lower part of the display is often provided with a menu selection key for menu selection. In addition to various symbols, numbers and functions, the keyboard can also be set up! User-defined health is also can be checked automatically . The operator can realize system management through the keyboard and display, input, store, edit and modify the numerical control program and related data. During processing, the screen can dynamically display system status and fault diagnosis report. In addition, the numerical control program and data can also be imported through the disk or the communication interface box.

The machine tool operation panel is mainly used for the operation of the machine tool in the manual mode, and the operation or preview of the machine tool in the automatic mode. There are various buttons and selection switches on it, which are used for starting and stopping of machine tools and auxiliary equipment, selection of processing methods, selection of speed magnification, etc. There are also digital tubes and signal displays. The operation panel of medium and small CNC machine tools is often integrated with the CNC panel, but there is a clear boundary between the two. The communication interface of the numerical control system, such as the serial interface, is permanent and on the machine tool operation panel.

Development trend

Since entering the 21st century, with the continuous development of CNC technology and the expansion of application fields, it has played an increasingly important role in the development of some important industries (IT, automobile, light industry, medical care, etc.) for the national economy and people’s livelihood. The digitization of required equipment is a major trend in modern development. In general, CNC lathes show the following three development trends.

High speed and high precision

High speed and precision are the eternal goals of machine tool development. With the rapid development of science and technology, the speed of replacement of electromechanical products is accelerated, and the requirements for the precision and surface quality of parts processing are also higher and higher. In order to meet the needs of this complex and changeable market, the current machine tools are developing in the direction of high-speed cutting, dry cutting, and quasi-dry cutting, and the machining accuracy is constantly improving. On the other hand, the successful application of electric spindles and linear motors, ceramic ball bearings, high-precision large-lead hollow internal cooling and ball nut strong cooling low-temperature high-speed ball screw pairs and linear guide pairs with ball cages and other machine tool functional components The launch of the machine tool has also created conditions for the development of high-speed and precision machine tools.

The CNC lathe adopts an electric spindle, which cancels the links such as belts, pulleys, and gears greatly reduce the rotational inertia of the main drive, improves the dynamic response speed and working accuracy of the spindle, and completely solves the problem of belts and pulleys when the spindle runs at high speed. Vibration and noise issues. The use of an electric spindle structure can make the spindle speed reach more than 10000r/min.

The linear motor has high drive speed, good acceleration, and deceleration characteristics, and has excellent response characteristics and following accuracy. The use of linear motor as servo drive eliminates the intermediate transmission link of the ball screw, eliminates the transmission gap (including backlash), the motion inertia is small, the system rigidity is good, and it can be precisely positioned at high speed, thus greatly improving the Servo accuracy.

Because of its zero clearance in all directions and very small rolling friction, the linear rolling guide pair has small wear and negligible heat generation and has very good thermal stability, which improves the positioning accuracy and repeatability of the whole process. Through the application of linear motor and linear rolling guide pair, the rapid moving speed of the machine tool can be increased from 10-20m/min to 60-80m/min, and the highest is 120m/min.

High reliability

The reliability of CNC machine tools is a key indicator of the quality of CNC machine tools. Whether the CNC machine tool can exert its high performance, high precision, and high efficiency, and obtain good benefits, the key depends on its reliability.

CNC lathe design, Structural design and Optimization

With the popularization of computer applications and the development of software technology, CAD technology has been widely developed. CAD can not only replace the tedious drawing work with manual work, but more importantly, it can carry out design scheme selection and static and dynamic characteristic analysis, calculation, prediction, and optimization design of the large-scale whole machine, and can carry out dynamic simulation of each working part of the whole machine. . On the basis of modularity, the three-dimensional geometric model and realistic color of the product can be seen in the design stage. The use of CAD can also greatly improve work efficiency and improve the one-time success rate of design, thereby shortening the trial production cycle, reducing design costs, and improving market competitiveness.