China CNC milling machine VMC850 is designed with a vertical bed structure, the feed axis is X, Y, Z three coordinate control, the main shaft is servo motor power drive, the power is 7.5Kw, the maximum speed is 8000rpm. The positioning accuracy of CNC milling machine is up ±0.01mm with the help of the double nut preload C3 ball Lead screw. The optional tool magazine is accurate and reliable for tool change; The machine tool numerical control operating system has customer choice, the machine tool can realize complex parts of various discs, plates, shells, cams, molds, etc.

China CNC milling machine construction features a perfect structural ratio. The major cast parts are scientifically rib reinforced. This CNC machine construction effectively extends service life and features a stable thermal effect and added dampening effect. China CNC milling machine installed 3 axes ball screws, hardened and precision ground slideways to achieve the best possible accuracy and maximum wear resistance. The optimized machine construction of Vertical Machining Center features maximum material stability, minimum deformation, and lifetime accuracy.

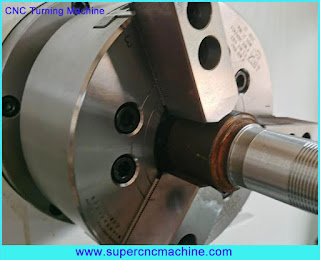

The Russian customer who has already bought a CNC lathe from us needed a Vertical Machining Center. After confirming the table size we recommended the China CNC milling machine VMC850. And we also sent to him the parameters and working video. Then he told that he needed the 4th axis, and also wanted the FANUC CNC system and tool magazine. After confirming all these configurations, we sent him the PI.

After about 30 days, the China CNC milling machine VMC850 was finished production, we invited him to check the machine, he asked for the working pictures and video. He was very satisfied with the CNC Milling Machine. Then he arranged the balance payment. He is a reseller, and we will have more cooperation in the future.

China CNC Milling Machine VMC850 Technical Parameters

| Model/Specifications | VMC850 |

| X-axis travel | 800 mm |

| Y-axis travel | 500 mm |

| Z axis travel | 500mm |

| Table size | 1000*500 mm |

| Maximum load of table | 500 kg |

| T-solt | 5*18*100mm |

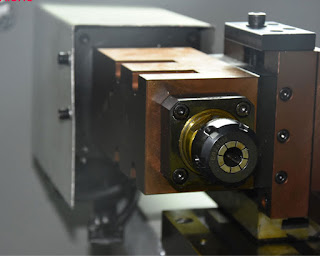

| Spindle taper | BT40 |

| Spindle maximum speed | 8000rpm |

| Rapid traverse | 48/48/48m/min |

| Spindle power | 7.5Kw/11kw |

| Cutting speed | 1-8000 mm/min |

| Spindle nose to table | 130-630mm |

| Spindle center to Surface rail | 525mm |

| Max tool diameter | 78/120mm |

| Positioning accuracy | ±0.0075 mm |

| Repeat accuracy | ±0.005 mm |

| Machine weight | 5600kg |

| Machine Size(mm) | 2600 *2300*2800 |

China CNC milling machine VMC850 Standard configuration:

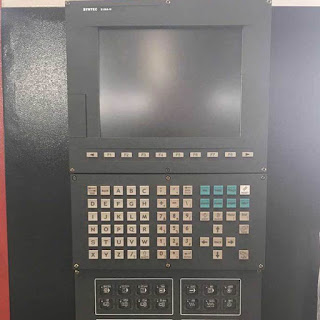

- KND2000 controller

- Spindle speed 8,000

- Automatic tool changer

- Automatic lubricating system

- Leveling kits

- Removable manual & pulse generator (M.P.G.)

- LED light

- Coolant system and tank

- Cycle finish indicator and alarm lights

- China cnc milling machine VMC850 Optional Accessories:

- Controller(Fanuc/Siemens/Heidenhain)

- German ZF gear box

- Automatic tool length measuring device

- Automatic work piece measurement system

- CNC rotary table and tailstock

- Oil skimmer

- Link/Screw type chip conveyor with chip bucket

- Linear scales (X/Y/Z axis)

- Coolant through tool holder

About HAISHU

Taian HAISHU machinery co., Ltd, is a professional manufacturer engaged in the research, development, production, sale, and service of CNC machine tools.

Our Products: CNC lathe, wheel CNC lathe, pipe CNC lathe, CNC turning center, Vertical machining center, etc.

Our Features: We can customized special CNC machines according to your requirements.

Our customers: We exported to United States, UK, Germany, Russia, Australia, Peru, South Korea, etc. more than 60 countries.

Our certification: we have CE certification and ISO9001 certification etc, Many of our products are developed by ourselves, and we have obtained corresponding patent certificates.

If you want to know more about our company and products, please contact us!