CNC instrument lathe is actually a branch of the CNC lathe. The biggest feature of the CNC instrument lathe is that the workpiece is mainly clamped with a spring chuck. This method is especially suitable for the clamping of batches of small workpieces. Only one push of the handle is needed to complete the clamping of the workpiece, and the clamping speed is less than one-third of the workpiece clamped by the manual chuck, the manual chuck clamps the workpiece and requires three movements, even much faster than hydraulic chuck clamping. A skilled worker can often operate 2-3 CNC instrument machines at the same time. Of course, CNC instrument lathes can also use manual chucks and hydraulic chucks to clamp workpieces, which should be optional accessories.

Introduction

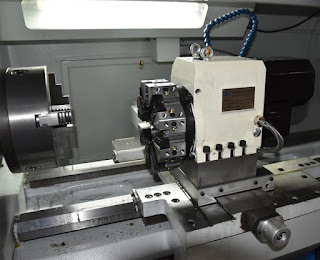

CNC instrument lathe, also known as CNC (Computer Numerical Control) instrument lathe, is a computer numerically controlled lathe.

Ordinary horizontal lathes rely on the manual operation of machine tools to complete various cutting processes, while the CNC lathe machine input the prepared processing programs into the CNC system, and the CNC system completes operations through the lathe. The servo motors of the X and Z coordinate axes control the action sequence, movement amount, and feed speed of the moving parts of the lathe, coupled with the steering of the spindle speed, and the automatic tool change system, so that various shafts with different shapes can be processed, such as slass or disc-like parts of revolution. Therefore, CNC instrument lathes are the most widely used machine tools at present.

Instrument lathe is a general term, it is mainly processing some small but not very precise parts. The instrument lathe can be used to process the oil needles, screws of the motorcycle carburetor. The more rudimentary ordinary instrument lathe has only one motor and one-bed body, which is very simple.

Principle

The instrument lathe adopts a spring chuck for quick clamping, the motor directly drives the main shaft, the large and small discs are operated quickly by hand, and the turning is controlled by vertical and horizontal positioning. The instrument lathe can be used to process external circle, internal circle, cutting off, end face, cutting groove, turning taper, drilling, reaming, tapping, milling, grinding, and other functions. It is widely used in electrical appliances, fasteners, automobile, motorcycle accessories, instrumentation, hardware appliances, cultural and educational supplies, film and television equipment, mechanical and electrical products, plumbing fittings, valves, bearing rings, shafts and other small parts, glasses manufacturing and other small workpieces It is the most ideal high-efficiency equipment in the hardware machining industry.

Due to the use of hand-push tool feed, quick clamping of spring chuck, thimble-type limit device, and rapid hand-operated operation, the motor directly drives the spindle to run, and the positioning controls the turning. Continuous processing of a single fixed type of workpiece and appearance is comparable. Ordinary lathes improve work efficiency by more than 10 times and are especially suitable for the processing of large batches and small parts. The CNC instrument lathe can replace other machine tools to save energy consumption.

Operation method

- In addition to using manual spring chucks to clamp workpieces, CNC instrument lathes can also use pneumatic spring chucks and hydraulic spring chucks to clamp workpieces.

- For short bars, spring backers must be set in the collet, not only can it be directly clamped in place without re-setting the tool, but also the workpiece can be automatically ejected after processing.

- For the mass production of long bars with a diameter of less than 20 mm, an automatic long material feeding system must be installed, which can greatly improve work efficiency. As for the method of pulling or pushing, it should be determined according to the workpiece.

- For mass-produced workpieces that can use short material automatic feeding, try to install an automatic feeding system.

- Those who can use the tool holder to clamp the tool should use the tool holder as much as possible. The tool holder can avoid the repeated positioning error and failure rate of the electric tool holder.

- If you want to increase the number of clamping tools, you can use the coexistence of electric tool rests and row tool rests. Our term is called dual-use electric row.

About HAISHU

HAISHU company is a manufacturer specializing in the production, design, and manufacture of CNC lathes, machining centers, and inclined bed CNC lathes equipped with linear guides and power turrets. We can customize machine tools to achieve special function requirements for customers.

At the same time, we also provide replacement, training, and maintenance services for CNC lathe systems. If you encounter difficulties in using CNC lathe machines or have any troubles, you can contact us to communicate. We will do our best to fulfill your request.