High speed, precision, composite, intelligence are the general trends in the development of the affordable CNC lathe, and they have achieved significant results in practicality and industrialization. The following are the typical aspects.

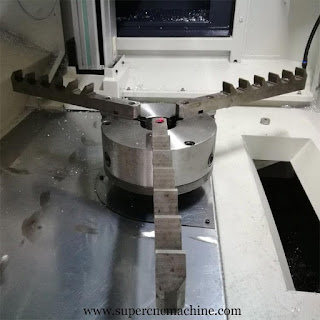

1. Further expansion of machine tool compounding technology with the advancement of Affordable CNC Lathe, the compound processing technology including milling-turning, turning-milling, turning-boring-drilling-gear processing, turning-grinding, forming-composite processing, has become mature increasingly, The precision and efficiency of compound processing are greatly improved. The concepts of “a CNC machine tool is a processing plant”, “one stop solution, and complete processing” are being accepted by more people, and the development of composite processing machine tools is showing a diversified trend.

2. There are breakthroughs in the intelligent technology of the Affordable CNC Lathe, which have been reflected in the performance of CNC systems. Such as automatic adjustment of interference and anti-collision function, the automatic exit of the workpiece from the safety zone after a power failure, power failure protection function, machining part detection and automatic compensation learning function, intelligent parameter selection function for high-precision machining parts, automatic elimination of machine vibration during processing, etc. At the practical stage, intelligence has improved the function and quality of the machine tool.

3. Industrial robots make the flexible combination more efficient. The flexible combination of robot and host is widely used, making the CNC lathe unit more flexible, further expanding functions, further shortening the flexible line, and making it more efficient. Robots and machining centers, lathe-milling machine tools, grinding machines, gear machining machines, tool grinding machines, electrical machining machines, sewing machines, stamping machines, laser machining machines, water cutting machine tools and other forms of flexible units and flexible production lines have begun to apply.

4. New advances in precision processing technology. The machining accuracy of CNC metal cutting machine tools has been improved from the original silk level (0.01mm) to the micron level (0.001mm) and some varieties have reached about 0.05μm. The precision cutting and grinding of ultra-precision Affordable CNC Lathe can achieve stability of about 0.05 μm and shape accuracy of about 0.01 μm. Special processing precision using light, electricity, chemistry and other energy sources can reach the nanometer level (0.001μm). Through the optimization of machine tool structure design, ultra-precision machining and precision assembly of machine tool parts, the use of high-precision fully closed-loop control and dynamic error compensation technologies such as temperature and vibration, the geometric accuracy of the machine tool are improved, and the geometric errors and surface roughness are reduced, Thus entering the era of sub-micron, nano-level ultra-finishing.

5. The performance of functional components is constantly improved. Functional components continue to develop in the direction of high speed, high precision, high power, and intelligence, and have achieved mature applications. All digital AC servo motors and driving devices, high-tech electric spindles, torque motors, linear motors, high-performance linear rolling components, high-precision spindle units, and other functional components are promoted and applied, which greatly improves the technical level of Affordable CNC Lathe.